Discover Material Insights: Comprehensive Material Testing Lab Services for Accurate Analysis

Wiki Article

Checking Out the World of Materials: Research at a Product Testing Laboratory

Are you curious concerning the fascinating globe of products and the groundbreaking research happening at product testing laboratories? In spite of what you may think, this field is not just for researchers in white laboratory coats. Exploring the globe of materials can be a eye-opening and interesting experience for anyone interested in recognizing exactly how day-to-day items are made and just how they perform. At a material testing lab, scientists make use of advanced methods to check out the residential properties and actions of different products, such as polymers, composites, and steels. This research study plays a crucial function in making certain the security and integrity of products in markets varying from aerospace to automobile. Join us as we explore the amazing explorations, applications, and future innovations in the field of products study.Sorts Of Products Studied

At a material screening research laboratory, you will certainly study a variety of materials for different purposes. From alloys and metals to polymers and compounds, the kinds of products checked out are varied and appealing. These materials are carefully analyzed and tested to establish their residential or commercial properties, performance, and viability for certain applications.Metals and alloys are frequently examined in material screening labs because of their widespread usage in markets such as construction, automotive, and aerospace. Scientists and designers examine their toughness, toughness, and corrosion resistance, to name a few variables, to guarantee that they meet security and quality requirements.

Polymers, including plastics and rubber, are one more substantial classification of products explored in these research laboratories. Their chemical composition, mechanical residential or commercial properties, and thermal actions are investigated to improve their performance in different applications such as packaging, medical tools, and electronics.

Composites, which are made by incorporating different materials, are also extensively looked into at material testing laboratories. These products use one-of-a-kind residential properties and qualities, making them suitable for applications that require both toughness and light-weight style, such as in the aerospace and sports markets.

Cutting-Edge Research Study Techniques

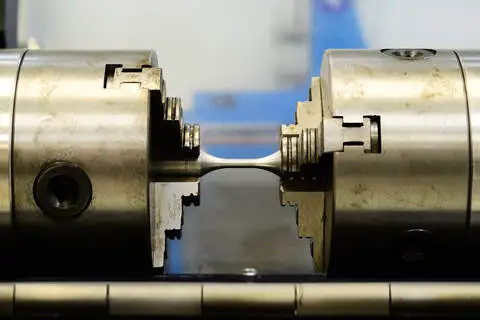

To explore the realm of sophisticated study techniques, material screening laboratories utilize ingenious approaches to assess and evaluate the residential properties of numerous products. These advanced techniques allow researchers to acquire a deeper understanding of the materials' attributes and actions, leading the means for the growth of better and brand-new products.One such strategy is electron microscopy, which uses a beam of electrons to create high-resolution pictures of products at the atomic degree. This makes it possible for researchers to research the microstructure of products, recognize issues, and establish their chemical structure.

An additional cutting-edge strategy is X-ray diffraction, which includes guiding X-rays onto a product and evaluating the resulting diffraction pattern - material testing lab. This method supplies beneficial information regarding the crystal structure of products, allowing researchers to recognize stages, procedure crystallographic criteria, and examine changes in the material's structure as a result of external elements

Material testing labs likewise make use of spectroscopy techniques, such as infrared spectroscopy and Raman spectroscopy, to research the interaction of materials with Learn More Here electromagnetic radiation. These strategies give insights right into the molecular structure and chemical composition of products, helping scientists to comprehend their functional homes.

Furthermore, scanning probe microscopy techniques, including atomic pressure microscopy and scanning tunneling microscopy, permit researchers to picture and control materials at the nanoscale. These techniques enable scientists to research surface area topography, procedure mechanical buildings, and also control individual atoms.

Significance of Material Screening

Recognizing the value of material testing is essential for scientists in a product testing laboratory. It permits you to examine and evaluate the residential or commercial properties and efficiency of different materials. By performing examinations, you can identify the viability of products for specific applications, guaranteeing their security and reliability.Material screening is vital for quality assurance. It helps you recognize any issues, weaknesses, or inconsistencies in the products, allowing you to make educated decisions regarding their use - material testing lab. This is especially important in sectors such as aerospace, automobile, and building and construction, where the stability of products directly influences the safety of items and structures

Furthermore, product testing allows you to maximize the style and production processes. By evaluating different products and their residential properties, you can select one of the most ideal ones for your particular application. This can bring about cost financial savings, improved effectiveness, and boosted product performance.

Applications in Various Industries

Material testing laboratories deal with a variety of markets, supplying valuable understandings and remedies for product applications. Whether it's the automobile market, aerospace industry, or building field, these laboratories play an important function in guaranteeing the quality and reliability of products utilized in different applications.In the automobile industry, product testing laboratories aid suppliers make sure the longevity and security of car components. From testing the toughness of engine parts to analyzing the deterioration resistance of body panels, these labs help in the growth and enhancement of automobile products.

In the aerospace market, material screening laboratories add to the style and manufacturing of light-weight yet solid materials for airplane and spacecraft. They check materials for their capacity to endure severe conditions such as heats and pressure changes, making sure the safety and performance of aerospace applications.

Additionally, product screening laboratories also satisfy sectors such as electronics, power, and clinical tools, supplying insights on the performance, dependability, and safety and security of materials utilized in these markets.

Future Technologies and Explorations

.jpg)

Final Thought

As you conclude your expedition of the globe of materials and the research conducted at a product screening lab, you realize the immense relevance of this image source area. From examining More Info various kinds of materials to using innovative research study techniques, product testing plays a vital function in various sectors. With constant developments and future innovations, this area holds the potential for impressive discoveries that will form the way we live and connect with products in the future.Are you curious about the interesting world of materials and the groundbreaking research occurring at material testing laboratories? At a product screening lab, scientists use sophisticated methods to explore the buildings and habits of various materials, such as polymers, composites, and steels.At a material testing research laboratory, you will examine a vast range of materials for numerous purposes.Comprehending the relevance of material testing is essential for researchers in a product screening laboratory.As you conclude your expedition of the globe of products and the research performed at a product testing lab, you recognize the tremendous importance of this field.

Report this wiki page